By Website Editor

•

April 30, 2020

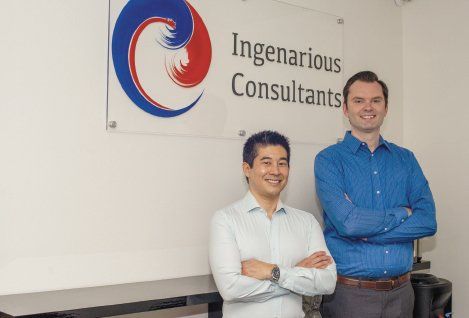

The number of startups venturing into the medical devices space is increasing, a positive outlook indeed. However, like any other startups, they face issues related to talent acquisition and budget constraints, resulting in delays to the market and interrupting the potential innovation of life-saving equipment. Raising capital, finding appropriate recourses, and hiring the right talents are also among the hurdles they face. But often times startups are challenged to even get off the ground, complete their initial design or build a prototype to demonstrate their ideas. Envisioning to tackle scenarios that immobilize the journey of such startups, Schieber–with his longstanding medical device research and development engineering experience—co-founded Ingenarious Consultants by partnering with manufacturing and operations engineerRandall Takahashi, who serves as its General Manager. For instance, early stage Startups may require the service of a certain engineering expertise and hiring a full-time engineer for that specialty would not be financially feasible. At inevitable and rather common situations like these, Ingenarious delivers the required service and assistance in an on-demand “stipulated time” basis. “We pioneer in helping startups, inventors and surgeons with their early-stage medical device development and guide their product from concept to design to manufacturing,” says Schieber. For this, Ingenarious deploys a team of talented, experienced professionals and leverages a unique “low overhead organizational framework”“We’ve structured our company as a combination of full-time engineers supplemented with part-time resources,” adds Schieber. The company adopts a unique, phased approach to structure the product development process in a financially viable manner. It starts with the close integration of Ingenarious’ team with that of the clients’ to understand their vision and requirements. There upon, the company works to identify the most crucial needs in materializing their ideas and vision. Ingenarious outlines the phases associated with product development, including the depiction of design elements, design requirements and design plans for prototyping, testing, and manufacturing. With this phased approach, the company offers startups end-to-end visibility about the scope of product development while reducing the risks in making financial and business decisions. Furthermore, in several instances, Ingenarious has even gone the extra mile supporting startups in applying for grants to raise capital for product development. Another key differentiator of Ingenarious over traditional consulting organizations is its in-house, fully functional lab that focuses on low volume, small, custom and complex parts and assemblies that many vendors shy away from. This allows its workforce to work independently of their clients’ internal resources which provides truly added bandwidth. This enables Ingenarious to provide clients with resources and expertise across every phase of product development from design, prototyping, refine and test, fabrication and pilot production. With such a value proposition, several startups have entrusted their success on Ingenarious. Recently, the company assisted a startup in building an advanced surgical model for their trainers, thereby eliminating the inconveniences associated with carrying human cadaver tissues. Ingenarious came up with the model, which was the combination of unique synthetic tissues and silicone. The company even went on to procure the necessary resources and capabilities to manufacture the product. “Today, we are producing 120 models per week, helping the client facilitate their training,” says Schieber. With a vision to become a full-service provider to medical device startups, the company is planning to extend its portfolio to assist clients all the way from idea to clinical trials. Ingenarious has recently appointed a regulatory affairs, quality assurance, executive-level person to provide necessary resources and assistance for clinical trials, and regulatory submissions. This new offering is available now for startups looking to draft their regulatory plans. Unlike its competitors who either use rudimentary casting methods or rely on high cost silicone injection molding vendors, Ingenarious has a robust silicone-processing unit in-house that creates injection molded quality silicone prototypes for low cost. “We are reinvesting our funds into advancing our silicone molding operation, including the addition of de-flashing equipment into our lab,” adds Schieber. Additionally, Ingenarious is also working on increasing its competence in CNC machining and 3D printing with an aim to deliver efficient services to clients.